GIGLER ELEKTRONIK

From the idea to the finished product

The company

From pattern to series

Performance

overview

Service

Competitive

advantages

Gigler Elektronik introduces itself

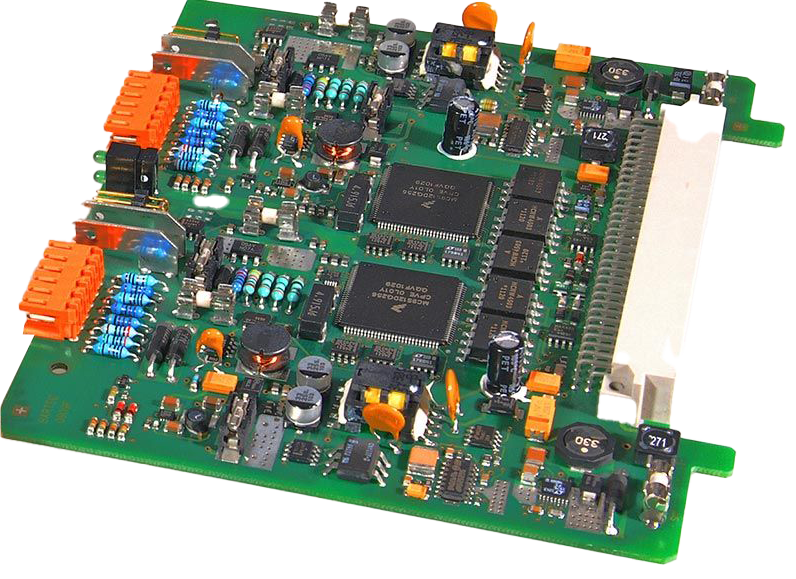

Founded in 1991, our company has continued to develop and has successfully relied on SMD technology since 1998. In 2016, we expanded our capacities by setting up a factory in Hungary.

Our commitment to technological innovation and quality makes us a reliable partner in the electronics industry.

This is what we stand for

As a full service provider, our goals and our vision are decisive for our success and the success of our customers.

- Goals

- Visions

From pattern to series

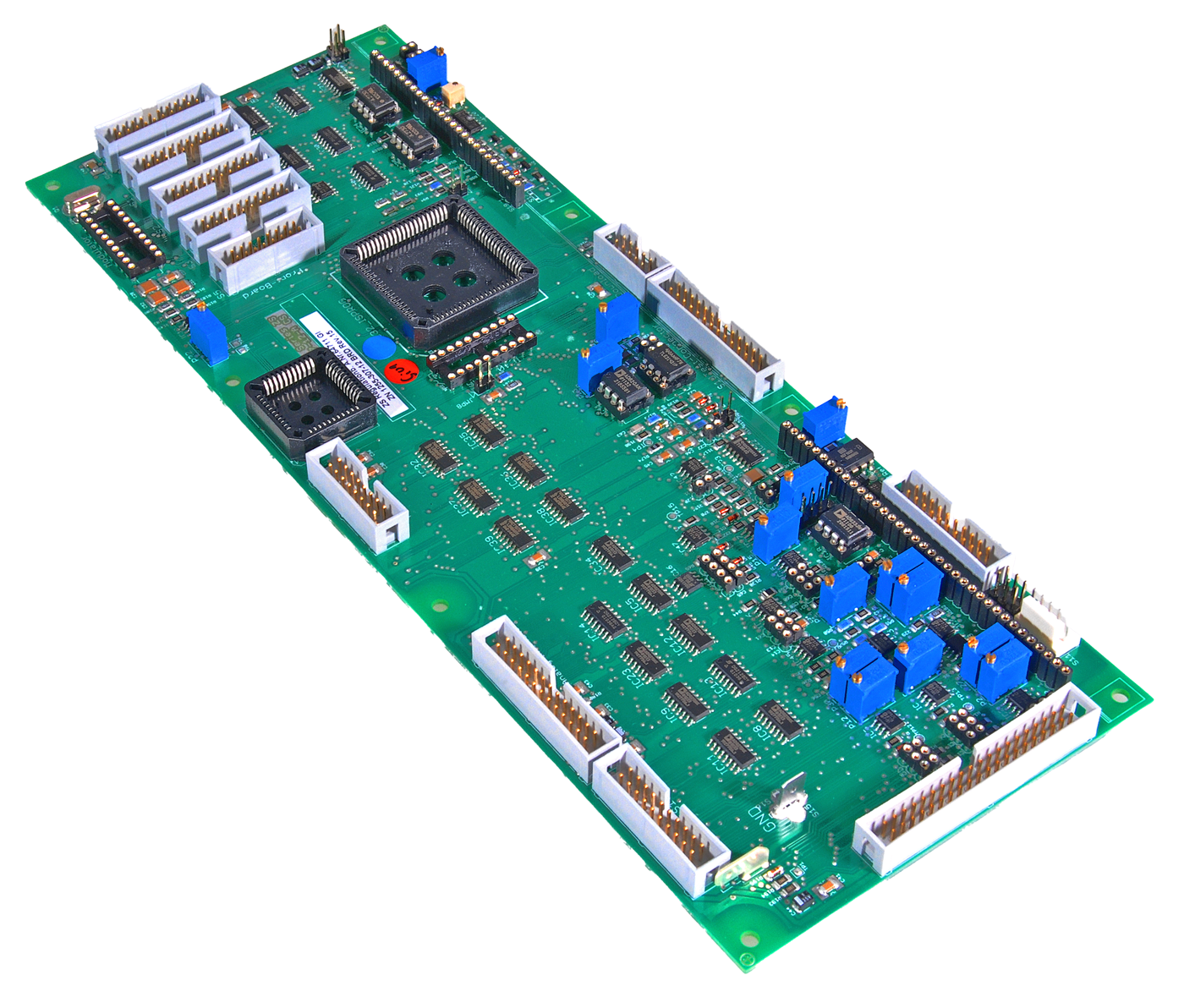

We realize your idea from the individual component to the module with a tested, finished system.

Overview of services

Electronics in all its facets is our passion - together with you we develop and manufacture your project.

Cable assembly is the production of ready-to-connect and ready-to-install cables, cable bundles and complete cable harnesses, fitted with connectors and contacts.

Whether devices, appliance parts or functional assemblies - we offer you suitable solutions for every task.

Service performance

We optimize your global materials management with advanced technologies and networked logistics systems to ensure efficient and punctual supplies to all production sites.

With a focus on sustainable procurement strategies and transparent supply chains, we ensure that both ecological and economic goals are achieved. This optimization enables us to react flexibly to market changes and always offer our customers first-class products.

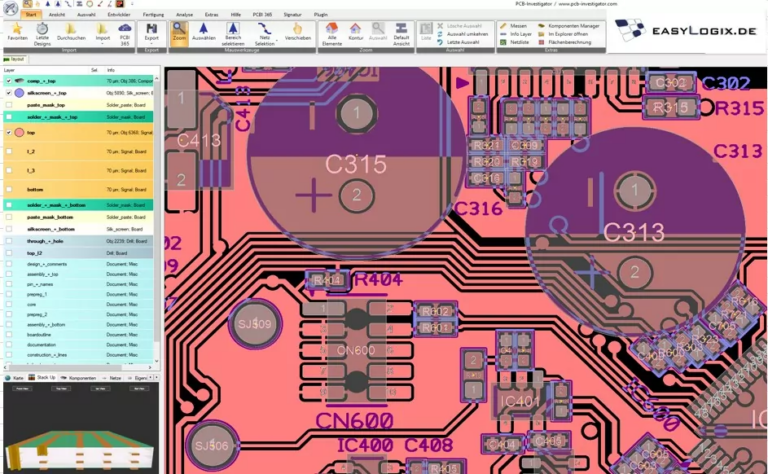

Gigler Elektronik offers high-quality testing and inspection services:

- AOI (Automatic Optical Inspection): Detection of manufacturing defects on printed circuit boards.

- ICT (in-circuit test): Checking electrical properties and connections.

- FAT (Factory Acceptance Test): Final inspection to ensure compliance with specifications.

- High voltage test: Testing the electrical insulation and load capacity.

State-of-the-art technologies guarantee the highest quality standards and customer satisfaction.

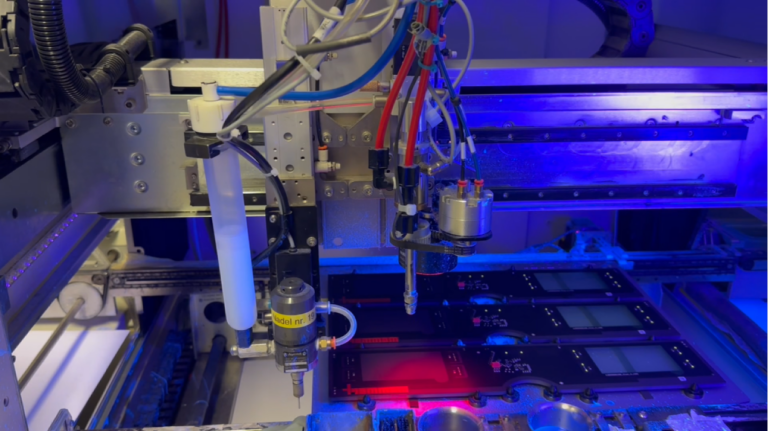

Electronic assemblies exposed to temperature and humidity can fail in the field. Our module protection by painting reliably protects your electronics from environmental influences such as moisture, dust and chemicals.

With precise painting techniques, we ensure that your assemblies remain durable and functional, even under extreme conditions. Rely on Gigler for optimum protection and the highest quality.

Gigler offers first-class appliance assembly services that guarantee the highest precision and quality. From component assembly to final production, we take care of the entire process and ensure that every device meets the highest standards.

Our experienced specialists and state-of-the-art technologies guarantee efficient and reliable installation that meets your specific requirements.

We offer first-class solutions in switch cabinet construction that impress with the highest quality and precision. With customized concepts that are precisely tailored to your requirements, from planning and production through to installation. With state-of-the-art technology and experienced specialists, we ensure that every control cabinet is optimally designed and reliably installed.

Competitive advantages

EMS service provider and full-service electronics manufacturing: assembly, coating and testing of printed circuit boards, device assembly and cable assembly.

Adherence to deadlines and flexibility are not foreign words for us - we also want to inspire our customers in this respect.

We assemble small, medium and large series SMD and THT production Highlight:

Assembly areas

1.000 mm * 460 mm 1.250 mm * 395 mm.

We do not manufacture any in-house products ourselves, which is why we remain loyal to our customers.