through the innovative PCB-I 365 data management platform.

Today’s manufacturing industry is faced with the challenge of having to offer ever shorter delivery times and increase production efficiency.

EMS service provider Gigler Elektronik GmbH

Gigler Elektronik develops and manufactures electronics, mechanics and cable products on behalf of customers with approx. 75 employees.

The assemblies are produced from batch size 1 (sample production) up to 500,000 units/year at the Konzell plant (Germany) and the Cegled plant (Hungary). Over 2200 different assemblies and devices are produced with a very modern and broad-based machine park.

Customers come from the following sectors: Industrial electronics, railroad technology and automotive.

In addition to well-trained and motivated employees, plant technology and a well-established customer/supplier network, the family business increasingly sees software tools as crucial to the company’s success in times of digitalization.

The challenge for an EMS company is to implement the product realization with as few interfaces as possible.

The challenge of digitalization in the EMS industry

In addition to the SAP merchandise management system, the layout and CAD programs, a solution was sought to manage the following topics:

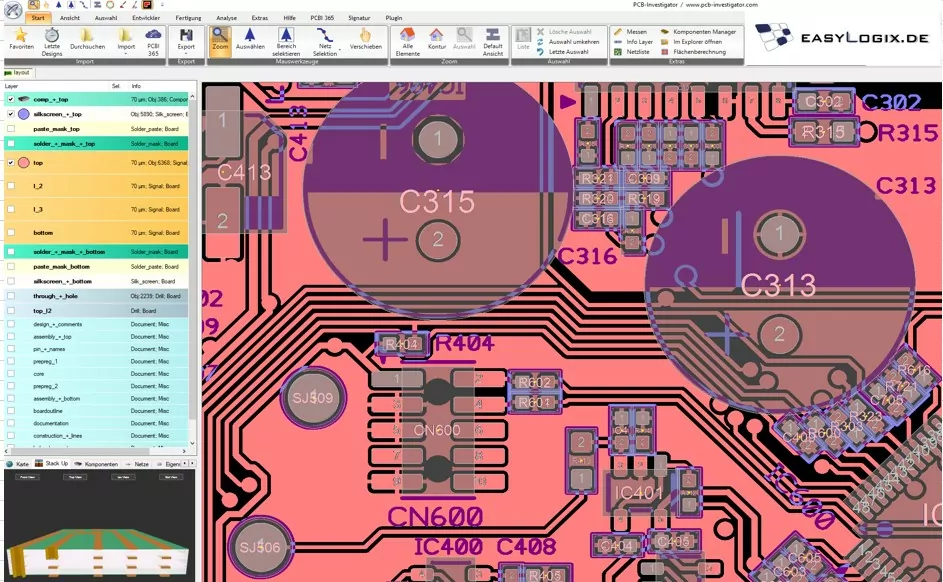

- Import and visualize CAE/CAD data from a wide variety of layout systems

- Audit-proof digital data management for Industry 4.0

- Comprehensible, transparent change management with targeted information flow

- Data optimization and import of external data (images, parts lists, 3D data, electrical information)

- Convert data into the required formats for PCB manufacturers, equipment manufacturers, placement and test machines

- Data interfaces to humans and production machines

- Simulate layouts for feasibility and identify deficiencies in advance

- Goal: 0-defect product design in coordination with the developers and customers

- Possibility of communicating analysis data with customers

- Issue electronic work instructions in real time (paperless production)

- Possibility of integration with existing machines and IT solutions in a holistic process view across the entire workflow.

- Expansion of product/process transparency

- Use of web-based data sources from external affiliated companies (data sheets, simulation data, availability)

- Ensure data security of sensitive customer data at all times

After considering the market, Gigler opted for the PCB-I 365 cloud management platform software from Easylogix, which works in conjunction with PCB-Investigator and has been integrated directly into the CAD/CAM software from Easylogix.

With this tool, Gigler Elektronik has created the possibility of meeting the requirements for error-proof and rational implementation.

The introduction was approached in small steps and gradually built up.

The competent support from Easylogix means that the customer can be offered added value, as the assemblies can be analyzed in advance. Gigler usually receives data formats such as: ODB++, IPC2581, GenCAD, Gerber 274x, PDF, Excel data etc. the required information.

Employees are provided with specific information and intelligent work instructions via screens.

This also means that all changes and their authors can be recorded so that all details of the project’s progress can be tracked. This means that every employee always works on the same file, making lost changes or mixed-up versions a thing of the past.

Gigler Elektronik takes advantage of the centralized management of all projects and thus brings everyone involved closer together – increased work efficiency, improved coordination and easier communication facilitate successful project completion. The PCB-I 365 management platform is the linchpin of the workflow.

Data is the new gold

Existing knowledge can ultimately optimize the company’s performance through evaluation and the resulting utilization of the data by means of intelligent data management.

With PCB-I 365, all data is therefore available regardless of location and time, so that nothing stands in the way of exploiting the full potential of existing knowledge. This focus on data is the ultimate in today’s business world, because: Data capital is company capital.

The consistency of the data flow from data management to data analysis is the unique selling point of the Easylogix data management platform.

Data can be used to build up a broad electronic knowledge of human and machine interfaces.

This know-how can then be incorporated into all production steps, and control loops ultimately lead to the independent optimization of existing processes.

This optimization in turn offers enormous savings potential for the entire production process.

Web-based checking sharing of designs (PCB-I Online)

The possibility of web-based testing and sharing of designs can also greatly improve the challenge of remote working and communication with the customer.

Gigler Elektronik therefore uses the web-based form of the PCB-Investigator PCB-I Online software. The web viewer technology from Easylogix enables direct access to the powerful CAD/CAM tool via a web browser. This allows designs to be verified without the need to install the desktop version.

Easylogix

The Regensburg-based company Easylogix is a team of developers that has been successfully designing CAD systems since 1999. Since the company was founded in 2008, the team has gradually grown to nine full-time developers. The E-CAD Library utilizes the experience of employees who have invested more than 50 “man-years” in the development of the basic PCB-Investigator software to date. The focus on innovation and performance is evident in all areas of application.