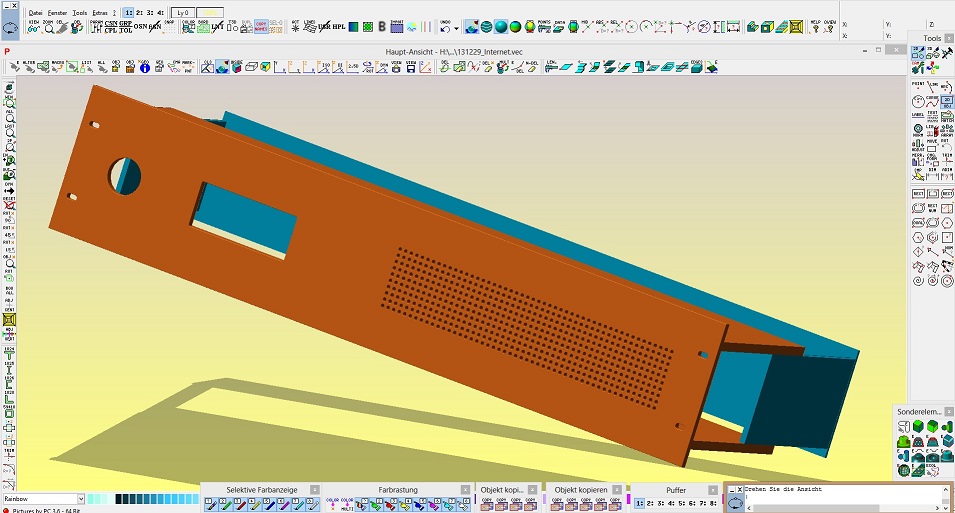

Design of mechanical modules and fixtures

We create various concepts according to your specifications (technical specifications and design matching) which we then convert to CAD models. Whether fixtures, device parts or functional modules, we have the appropriate solutions ready.

We would be glad to help you with sample parts and for implementing them into series application.

The following import / export systems can be used for 2D/3D design data exchange:

STEP, VDA, 3DS, DXF, IGES, GBR, STL, SAT, DXF, AI, EPS, HPGL, etc.

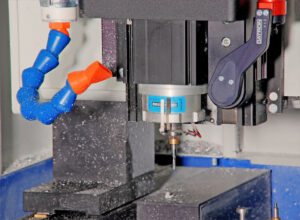

CNC-Milling

CAD / CAM systems are available for programming.

Engraving or milling of front panels and mechanical parts as individual parts up to medium sized batches are done on CNC systems.

A corresponding post-treatment in the plating shop, sandblasting and printing etc. can be provided at any time. We look forward to your enquiry.

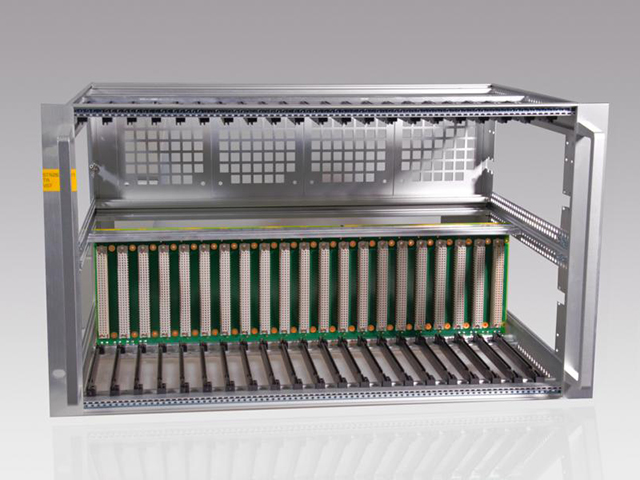

Mechanical Assembly

The components are assembled according to specifications on the functional parts and tested.

We would be glad to assemble the modules as well. As EMS provider, we also assume responsibility for procuring the materials and the entire logistics for your product.

Examples

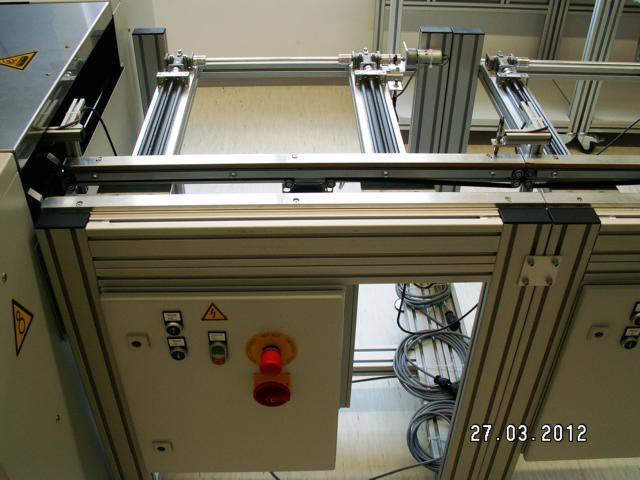

We also fabricate individual solutions e.g.

Assembly tables can also be fabricated with platform.

We make these as per your specifications.

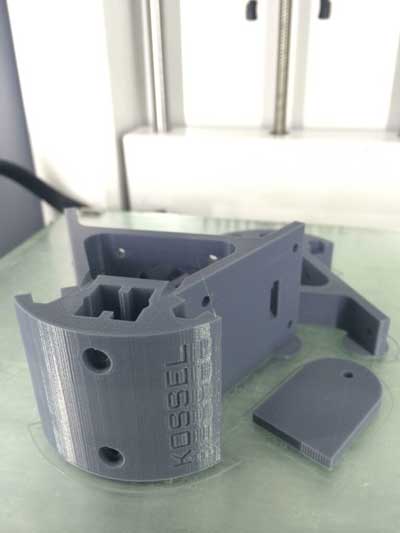

3D print

We purchased a 3D printer in order to build assembly aids and mounting aids both easier and faster. Also, building samples and prototypes for cases are more efficient with 3D printing.

Highlights & details

- Prints objects with a size up to 223 x 223 x 305 mm

- Highest resolution in its class with a layer thickness of only 0.02 mm

- Very fast with a printing speed up to 300 mm/s

- Interchangeable print nozzles for a highly detailed and fast print (0.25 mm, 0.4 mm, 0.6 mm, 0.8 mm)

- Extruder with double active cooling under the nozzle

- Heated printing rack causing little tension and little default

Further information

- A .STL-file is necessary for printing

- Print material PLA or ABS; PLA has better print properties

Plastics Technology

What’s new: Since January 2013, we manufacture now also plastic parts for you.

Our portfolio mainly includes:

- Technical plastic parts and modules

- Design parts

- Component parts and components

- Injection moulds

Sheet metal forming

Flexible production technology and plating

We expand our portfolio in sheet metal forming with our partner „Schierer“:

- We design and build cases, individual components and comprehensive solutions made of steel, high-grade steel and aluminum.

- We are your competent and reliable partner in terms of sheet metal working, powder coating, wet paint and montage.

- Ideal partner for galvanic and chemical coats – We know what’s possible and not. We know the materials.

You’ll get more information about Schierer here.

Our services

Consultation / construction

Purchase

Sales / production planning

Quality management / environmental management

Production

Surface technology

Montage

Logistics / vehicle fleet

Production and technologies:

Non-cutting production

cutting production

Post-production

Bending technology

Press-in technology

Connection technology

Welding

Surface technology

Montage

Plating:

Decorative surface

Functional surface

Pretreatment / follow-up treatment

Quality management / environmental management

AOB