Production

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Soldering technology

Lead-free soldering for protecting the environment!

Vapour phase soldering system

Vapour phase soldering is the most gentle soldering method for components because the components are subjected to the minimum amount of temperature stress in this method compared to other soldering methods. Another advantage of this soldering method is the uniform heating and profile design of large and small components.

The soldering process is carried out in an oxygen-free vapour phase, which ensures that the solder joints are optimally and gently fabricated with flux. The process is used for lead-containing and lead-free soldering at Gigler Elektronik.

Reflow soldering

In reflow soldering, the printed circuit board is transported inline into a nitrogen reflow soldering furnace. Using different heating zones, the printed circuit board is preheated and soldered in the peak zone. The soldering profiles are computer-controlled and monitored. The nitrogen for the soldering process is generated in the internal air separation system. The residual oxygen content of the module can thus be adjusted.

Wave soldering

In wave soldering, a flux is applied to the circuit board using a spray fluxer in selective spraying method. In the process, the circuit board is held in a solder frame which transports the module through the soldering unit. The module is pre-heated in the pre-heating station and the flux is activated. The soldering unit consists of a solder pan with hot solder, which is applied to the solder joint using a solder pump. Then the module is cooled and is ready for final inspection.

Gigler Elektronik can provide lead-containing and lead-free soldering for your products.

Selective soldering

The percentage of SMD components is gradually increasing in modules with a small amount of THT components. In this case, Gigler Elektronik provides an alternative selective soldering method (lead-containing / lead-free) as well as solderless pressfit technology.

Test systems - Endurance testing of products

Electrical test

While conducting the functional check of different modules, all faults cannot always be detected with visual test.

Supplementary to this, Gigler has different test systems for optimising the process of inspection:

- ICT (= In-Circuit-Test): In this test, the measured value of the electrical strands in components is tested.

- Colour intensity / Light colour: The measurement takes place with the help of light sensors.

- FAT (= functional and calibration test): The circuit boards are tested with respect to their function.

Principally, the following applies:

The earlier the fault is detected, lesser are the costs incurred. Since the adapter is integrated inside, we can cater to your requirements and support you while designing the layout on DFT (Design for Testability).

Have we aroused your interest and do you want us to send you a non-binding offer?

Alternating Climate Test Guarantees Product Quality

Gigler always gives its best to offer quality on a high level.

We ensure reliability; weak spots are detected at an early stage. Therefore, Gigler has invested in alternating climate tests.

Burn-In-Test

A burn-in test simulates the aging of a component which makes it possible to identify weak spots of components or material. The burn-in test usually has higher temperatures than a run-in test; experience has shown that defective components, which haven’t had any noticeable weak spots in previous short tests, burn out.

Components that survive the burn-in test are supposed to have a long service life.

A temperature test lasting more than 24 hours is recommended especially for highly failure-resistant products. The cabin contains 340 liters. It can easily test entire 19 Inch racks up to 12 HE.

Characteristics:

- type: ESPEC PL2 J

- temperature: – 40 – + 180 °C

- Humidity: 10 – 98% RH

- Cabin size: 500 x 750 x 600 mm³ (Height x Width x Depth)

- Microprocessor control

- Heating rate: 3k/min

- Cooling rate: 2k/min

Run-In-Test

A run-in test is testing for the components’ reliability. Therefore, the components undergo a cyclical change of temperature while being plugged to supply voltage. The temperature range that needs to be tested is usually the same as later in practice

Paint

Protection of electronic modules has gained more importance in the recent years; particularly, the reliability and safety against failure has been increased considerably.

Paint offers a series of advantages: Protection against humidity and surroundings, better thermal properties as well as improved vibratory characteristics and, last but not least, increased service life, just to mention a few.

For example, if you have electronic items, which are exposed to atmospheric influences, we can offer you appropriate safety measures.

Gigler Elektronik offers you an all-round service:

- Consultation for designing circuit boards

- Sample / Prototype manufacturing

- Creation of paint carriers / paint stencils

- Painting of modules (spraying, selective

- painting, dip coating)

- External collaboration in project groups

- Trainings in electronic production

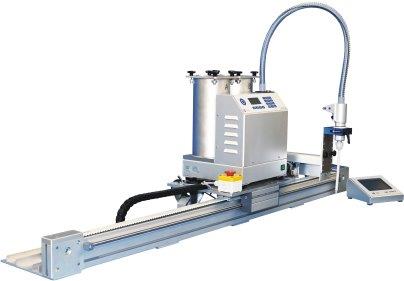

Potting technology

As of February 2017 we can offer potting technology!

We use a grouting device in order to cast LED light strips up to 3.5 m lengths. For transparent potting compound.

Potting is very appropriate, especially for waterproof applications of light components with a higher environmental pollution.